Cherry

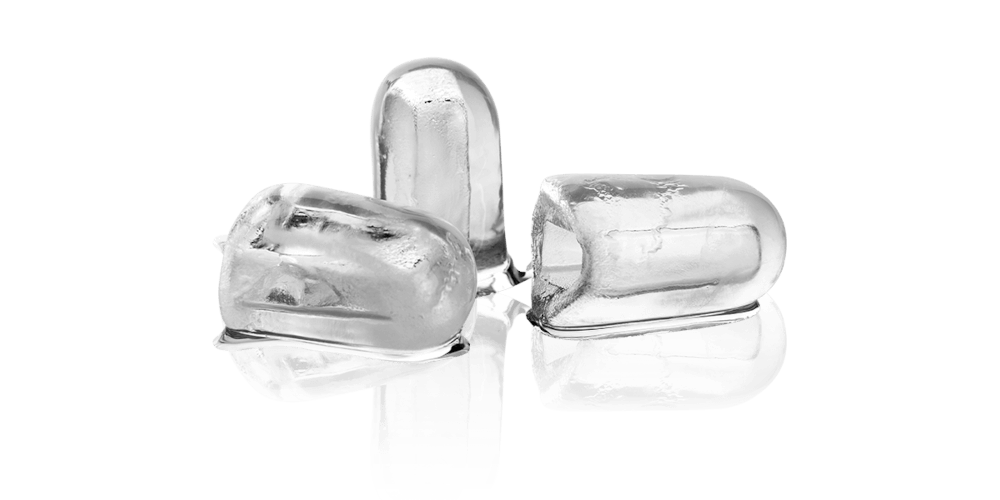

BRIGHT CUBE

A full and structured ice cube, with rounded surfaces for a prolonged beverage cooling. Its particular transparency is highly appreciated in any context of use.

Cherry

A full and structured ice cube, with rounded surfaces for a prolonged beverage cooling. Its particular transparency is highly appreciated in any context of use.

Coco

A hollow ice cube, with wide

surface for fast beverage cooling.

With a simple and essential shape, it grants an extreme flexibility of use.

Coco

HOLLOW CUBE

A hollow ice cube, with wide

surface for fast beverage cooling.

With a simple and essential shape, it grants an extreme flexibility of use.

Maracuja

MODULAR CUBE

Full and square ice cube,

available in three different sizes

DICE, HALF- LARGE and LARGE. The perfect solution for quick beverage cooling.

Maracuja

Full and square ice cube,

available in three different sizes

DICE, HALF- LARGE and LARGE. The perfect solution for quick beverage cooling.

Berries

Granular ice is an asset in many sectors, thanks to its multiple uses: from food conservation and display, to cocktails preparation, to applications is SPAs, in the world of cosmetics, in medical and hospital environments.

Berries

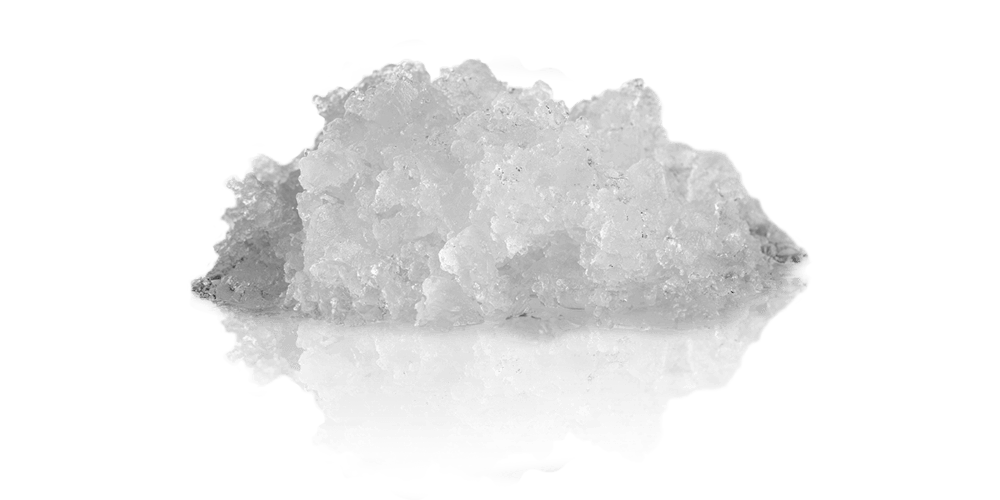

FLAKE ICE

Granular ice is an asset in many sectors, thanks to its multiple uses: from food conservation and display, to cocktails preparation, to applications is SPAs, in the world of cosmetics, in medical and hospital environments.

Grape

NUGGETS

Nuggets-shaped has the characteristics of being both compact and pleasant to chew, being half-way between granular ice and solid ice cubes.

Grape

Nuggets-shaped has the characteristics of being both compact and pleasant to chew, being half-way between granular ice and solid ice cubes.

Almond

With an average temperature of -7°C and a thickness between 0,9 and 1,2 mm,

the ice made by the Almond line machines is the coldest and driest available, unique in its kind. Solid and dry, ice-flakes have a great surface of contact, for a fast cooling.

Almond

SCALE ICE

With an average temperature of -7°C and a thickness between 0,9 and 1,2 mm,

the ice made by the Almond line machines is the coldest and driest available, unique in its kind. Solid and dry, ice-flakes have a great surface of contact, for a fast cooling.

Tropical

DISPENSER

Those ice dispensers are the optimal solution for canteens, self-services, hotels and pubs where it is necessary to have

perfectly dosed ice, and quickly.

Tropical

Those ice dispensers are the optimal solution for canteens, self-services, hotels and pubs where it is necessary to have

perfectly dosed ice, and quickly.

Mango

The Icematic commercial ice bins are entirely designed internally to match whatever users’ need.

Mango

STORAGE

The Icematic commercial ice bins are entirely designed internally to match whatever users’ need.